Quality process of Emiklo.

Quality is of great importance for Emiklo.

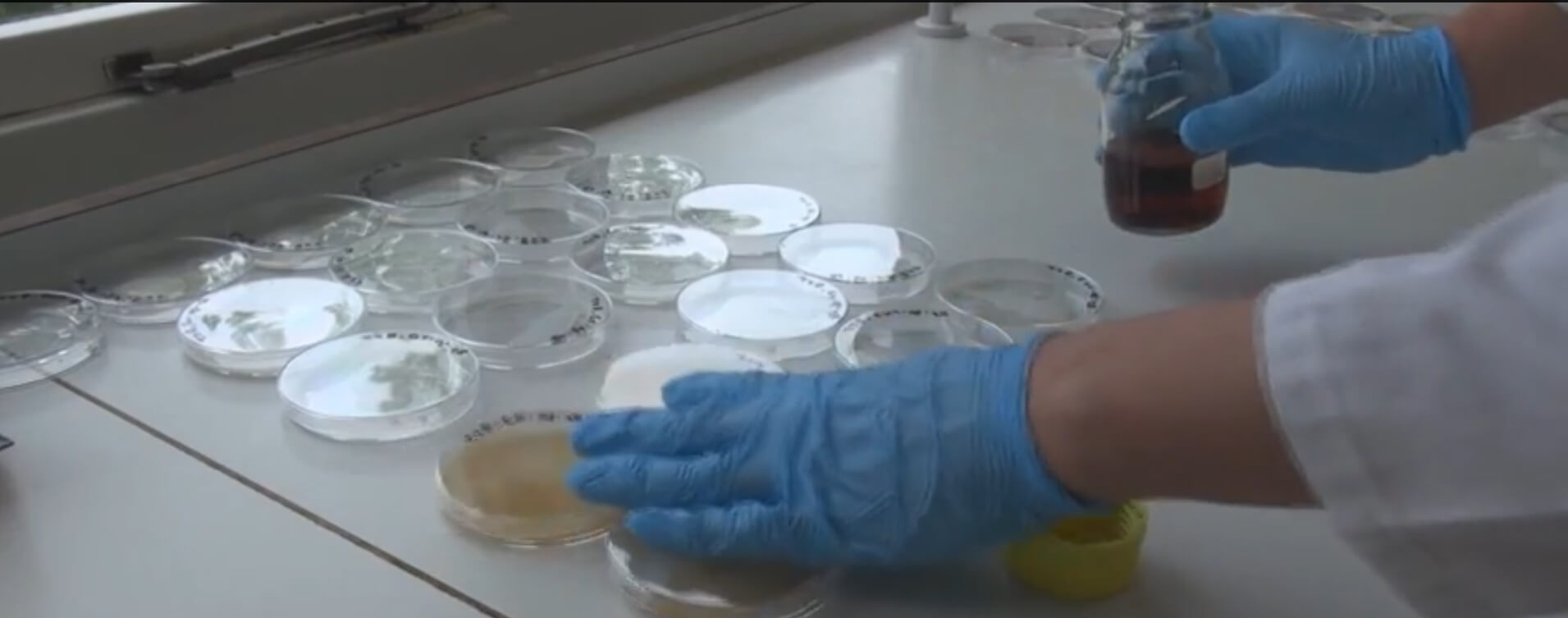

During our process we check the quality continuously, whether it is quality of the equipment, quality checks of the milk or quality checks before the goods arrive at the customer. We have a preventive monitoring system active.

The following steps are of particular importance:

1. Farm

The process start at the farm. The production of milk is secured by a safety system. The cows at the farm are subject to a veterinary inspection. The milk is stored at 2 to 4 degrees Celsius in a clean tank.

2. Arrival at factory

When the milk arrives at the factory, samples are taken and analysed. In these analyses it is checked if the milk meets the requirements. After approval the milk will be processed and spray dried. Other ingredients that arrive at the factoy are treated similarly.

3. Production

Processing, temperatures and in-line controls are carried out as written down in the Quality Assurance Manual. The whole production process is regularly audited by the auditing authorities (SGS) and by government (nVWA/COKZ).

4. Packing

Our standard packing is in sachets, which are air and light tight. Each product is marked by a batchnumber and a unique individual number.

5. Tracking and Tracing

Each ingredient and packing material receives a unique number. Our suppliers work with the same tracking system, so that every ingredient can be traced back to its origin.

By ensuring that each part of the process is of an excellent quality, we can ensure that the quality of the final products is maintained.